5S training, rooted in lean management and workplace organization, optimizes ergonomic workspace design through reducing clutter, promoting good posture, and fostering efficiency. This continuous improvement methodology includes sorting, setting in order, shining (cleaning), standardizing, and sustaining to enhance productivity, minimize musculoskeletal disorders, and adapt workspaces to employee needs. By implementing 5S, organizations create structured environments boosting employee well-being, focus, and task performance through process standardization and continuous improvement.

Ergonomic workspace design is a game-changer in fostering employee productivity and well-being. In today’s digital era, navigating a bustling workspace requires understanding ergonomic principles, efficient organization, and continuous improvement. This article delves into the essence of these concepts through key sections: exploring ergonomic fundamentals, leveraging 5S training, implementing lean management techniques, utilizing process standardization, and adopting effective 5S continuous improvement strategies. By embracing these practices, folks can transform their workspaces into vibrant environments that enhance productivity and overall satisfaction.

- Understanding Ergonomic Principles for Workspace Design

- The Role of 5S Training in Creating Efficient Workspaces

- Lean Management Techniques for Workplace Organization

- Implementing Process Standardization for Continuous Improvement

- Tools and Strategies for Effective 5S Continuous Improvement

Understanding Ergonomic Principles for Workspace Design

Ergonomic workspace design is rooted in understanding and applying fundamental ergonomic principles to create environments that support productivity, health, and well-being. These principles focus on optimizing human performance by reducing physical stress and promoting good posture during various tasks. One effective framework for achieving this is the 5S training methodology, which encompasses Sort, Set in Order, Shine (cleanliness), Standardize, and Sustain. This system, inspired by lean management and workplace organization principles, encourages process standardization and continuous improvement, ensuring that workspaces remain efficient and ergonomic over time.

By integrating 5S concepts into workspace design, organizations can foster a culture of order and efficiency. Sort involves eliminating clutter and keeping only essential items within reach; Set in Order ensures tools and equipment are organized for easy access; Shine emphasizes maintaining a clean, safe environment; Standardize establishes consistent practices; and Sustain focuses on continuous evaluation and adjustment to maintain optimal ergonomic conditions. These principles, when implemented through 5S continuous improvement, create a dynamic workspace that adapts to the needs of employees, enhancing productivity while minimizing the risk of musculoskeletal disorders.

The Role of 5S Training in Creating Efficient Workspaces

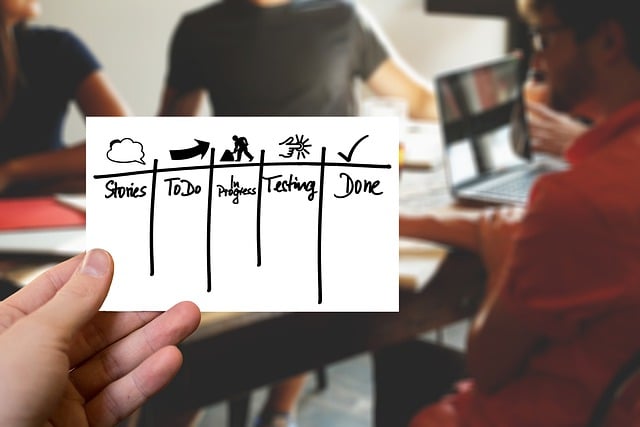

Implementing 5S training is a powerful strategy for transforming chaotic workspaces into streamlined environments that promote productivity and employee well-being. This lean management approach, rooted in Japanese manufacturing principles, emphasizes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining. By teaching employees these fundamental principles, organizations can achieve remarkable efficiency gains.

5S continuous improvement drives process standardization, ensuring tasks are completed in the most logical and efficient manner. Each step is meticulously planned and executed, reducing waste and enhancing overall workplace organization. This method not only improves productivity but also fosters a culture of order and discipline, where every tool, material, and piece of equipment has its designated place. Such structured environments contribute to reduced stress levels among employees, allowing them to focus better on their tasks.

Lean Management Techniques for Workplace Organization

Implementing Lean Management techniques like 5S training is a powerful strategy for transforming your workspace design into an organized and efficient environment. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—is a continuous improvement process that emphasizes process standardization. By applying these principles, you can create a workplace free from clutter, enhancing productivity and reducing wasted time.

Workplace organization through 5S training encourages employees to take an active role in maintaining a lean workspace. It fosters a culture of order and discipline where every item has its designated place, streamlining workflows and improving overall efficiency. Regular 5S practices ensure that standardized processes are maintained, allowing for better collaboration, reduced errors, and an improved overall work experience.

Implementing Process Standardization for Continuous Improvement

Implementing Process Standardization for Continuous Improvement is a key aspect of ergonomic workspace design, rooted in lean management principles and 5S training methodologies. By systematically organizing and streamlining workplace processes, organizations can achieve greater efficiency and enhance employee comfort. This involves identifying and documenting each step in a workflow, ensuring clarity and consistency across all tasks. Standardized processes not only reduce errors but also create an environment conducive to continuous improvement initiatives.

Regular reviews and updates of these processes are essential to adapt to changing demands and technologies. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—serves as a powerful framework for achieving and maintaining workplace organization. Incorporating these practices fosters a culture of efficiency, where every element in the workspace has a designated purpose, promoting better posture and reducing the risk of musculoskeletal disorders.

Tools and Strategies for Effective 5S Continuous Improvement

Implementing effective 5S training is a powerful tool for anyone looking to enhance their workplace organization and embrace lean management principles. The 5S methodology—Sort, Set in Order, Shine, Standardize, Sustain—provides a structured approach to workspace design and continuous improvement. It starts with sorting through unnecessary items, organizing work areas, and promoting cleanliness (Shine). Next, tools and equipment are arranged for easy access (Set in Order), and standardized procedures ensure consistency. The final step, Sustain, reinforces these practices and encourages ongoing process standardization.

This strategy not only creates a visually appealing and efficient workspace but also boosts productivity by minimizing waste and streamlining workflows. By integrating 5S continuous improvement into your routine, you can maintain an orderly environment, improve employee satisfaction, and drive operational excellence. Effective 5S training empowers individuals to take ownership of their workspace and contribute to the overall success of the organization through thoughtful process design.

In conclusion, ergonomic workspace design combines principles from 5S training, lean management, and process standardization to create efficient, organized, and comfortable work environments. By implementing these strategies, businesses can enhance employee productivity, reduce injuries, and foster a positive work culture. Continuous improvement through tools and strategies for 5S continuous improvement ensures that workspaces remain optimized over time, making it a valuable investment for any organization seeking to maximize its human capital.