Lean manufacturing focuses on eliminating waste and maximizing value through 5S training (Sort, Set in Order, Shine, Standardize, Sustain) for efficient workplace organization. This drives continuous improvement via Kaizen events, value stream mapping, and regular workflow reviews to standardize processes, enhance quality, reduce costs, and boost productivity across industries. Workplace organization, powered by 5S, optimizes tasks, improves accessibility, fosters collaboration, and underpins lean management's success in revolutionizing manufacturing processes.

Discover the transformative power of Lean manufacturing principles, a game-changer in industrial efficiency. This comprehensive guide explores essential practices like 5S training methodologies, empowering organizations to optimize their operations. Learn how lean management techniques foster workplace organization and drive continuous improvement. From process standardization to efficient workflow design, these strategies ensure every step enhances productivity. Uncover the secrets behind successful lean implementation, leading to reduced waste, improved quality, and a vibrant, high-performance work environment.

- Understanding Lean Manufacturing Principles

- The Core 5S Training Methodologies

- Lean Management: A Comprehensive Overview

- Workplace Organization for Continuous Improvement

- Standardizing Processes for Efficiency

Understanding Lean Manufacturing Principles

Lean manufacturing principles focus on eliminating waste and maximizing value in production processes. At its core, this approach emphasizes efficient workplace organization through practices like 5S training—a system that includes sorting, setting in order, shining (cleanliness), standardizing, and sustaining. By implementing these steps, organizations can achieve a highly organized, streamlined environment where every element contributes to the overall process.

The lean management philosophy goes beyond initial setup; it drives continuous improvement through processes like Kaizen events and value stream mapping. This involves regularly reviewing workflows, identifying inefficiencies, and standardizing processes to ensure consistency and quality. The goal is not just to meet current standards but to continually raise them, fostering a culture of ongoing enhancement and optimization.

The Core 5S Training Methodologies

The 5S training methodology is a cornerstone of lean manufacturing and workplace organization. It comprises five key disciplines: Sort, Set in Order, Shine (or Clean), Standardize, and Sustain. This systematic approach enables organizations to achieve remarkable efficiency and process standardization through continuous improvement. By sorting through unnecessary items, setting up work areas for optimal productivity, shining (cleaning) to maintain a visually appealing environment, standardizing processes, and sustaining these practices over time, businesses can create a leaner, more productive workplace.

5S continuous improvement is not just about achieving an organized workspace; it’s a management philosophy that fosters a culture of quality and efficiency. Each ‘S’ represents a step in a journey towards eliminating waste and enhancing productivity, thereby driving organizational success through streamlined processes. This simple yet powerful framework can be applied across various industries, making it a versatile tool for any organization aiming to adopt lean management principles.

Lean Management: A Comprehensive Overview

Lean Management is a comprehensive approach that focuses on eliminating waste and maximizing value in manufacturing processes. It’s built upon the foundational principles of 5S training—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—which aim to transform workplaces into highly organized, efficient environments. This method involves rigorous process standardization, enabling companies to streamline operations, reduce errors, and enhance overall productivity.

The continuous improvement aspect of lean management drives organizations to regularly assess their practices and identify areas for enhancement. By fostering a culture that values workplace organization, lean management ensures every step in the production cycle is optimized, leading to cost reduction, improved quality, and enhanced customer satisfaction.

Workplace Organization for Continuous Improvement

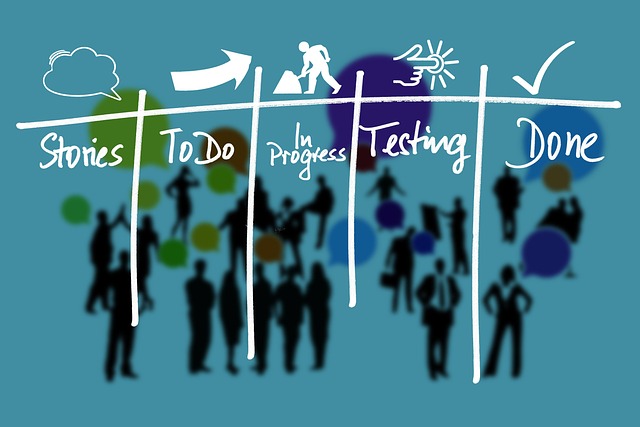

Workplace Organization is a cornerstone of Lean manufacturing, fostering a culture of continuous improvement. The 5S training methodology, integral to lean management, provides a structured framework for organizing and maintaining an efficient workspace. This involves sorting through unnecessary items, setting things in their proper place, shining a light on hidden areas, standardizing processes, and continually sustaining the improved environment.

By implementing these practices, organizations can enhance workflow efficiency, reduce waste, and improve overall process standardization. A well-organized workplace enables employees to quickly access necessary tools and resources, minimizing downtime and maximizing productivity. This collaborative approach to 5S continuous improvement not only benefits individual teams but drives organizational success by creating a streamlined and responsive production environment.

Standardizing Processes for Efficiency

In lean manufacturing, standardizing processes is a key principle driving efficiency and productivity. This involves implementing structured systems, like 5S training, to create a highly organized and streamlined workplace. The ‘5S’ methodology stands for Sort, Set in Order, Shine (or clean), Standardize, and Sustain, providing a framework for maintaining order and minimizing waste.

By teaching employees the 5S principles, organizations can ensure that tasks are completed in an efficient manner, with every step of a process clearly defined and optimized. Process standardization facilitates continuous improvement, as it allows for regular reviews and adjustments to work procedures, ultimately leading to enhanced productivity and reduced operational costs.

Lean manufacturing is a powerful approach that transforms businesses by eliminating waste and maximizing efficiency. By implementing the core principles outlined in this article—including 5S training methodologies, lean management practices, and workplace organization strategies—organizations can achieve remarkable improvements in productivity and overall operational excellence. Standardizing processes is a key aspect of lean manufacturing, ensuring consistent and streamlined operations. Adopting these principles fosters a culture of continuous improvement, enabling businesses to stay competitive and thrive in today’s market.