The Lean Workplace Philosophy, inspired by Toyota's manufacturing practices, focuses on eliminating waste and maximizing productivity through systematic workplace organization. The 5S training method (Sort, Set in Order, Shine, Standardize, Sustain) transforms spaces into efficient environments, empowering employees to identify and implement solutions for continuous improvement. This approach leads to enhanced productivity, reduced errors, improved job satisfaction, and safer work environments. By combining 5S training with lean management principles, organizations can achieve operational excellence through streamlined processes, process standardization, and a culture of ongoing enhancement.

“Discover the transformative power of Lean workplace philosophy, a systematic approach to enhancing efficiency and productivity. This comprehensive guide explores the core principles of 5S training, its pivotal role in organizing bustling workspaces, and its synergetic relationship with lean management techniques. From streamlining processes to implementing continuous improvement, learn how 5S continuous improvement guides and process standardization create a consistent, waste-reducing environment. Dive into these real-world applications and success stories for insights that will revolutionize your workplace.”

- Understanding the Lean Workplace Philosophy: A Foundation of Efficiency

- The Core Principles of 5S Training and Its Role in Workplace Organization

- Lean Management Techniques for Streamlining Processes and Boosting Productivity

- Implementing Continuous Improvement with 5S: A Step-by-Step Guide

- Process Standardization: Creating Consistency and Reducing Waste

- Real-World Applications: Success Stories of Lean Workplace Transformation

Understanding the Lean Workplace Philosophy: A Foundation of Efficiency

The Lean Workplace Philosophy is a systematic approach to workplace organization and efficiency inspired by Toyota’s manufacturing practices. At its core, this philosophy emphasizes eliminating waste, maximizing productivity, and continuously improving processes. The foundation lies in the 5S training method—Sort, Set in Order, Shine (Clean), Standardize, Sustain—which transforms spaces into organized, streamlined environments. This systematic organization ensures that tasks are accomplished efficiently, resources are utilized optimally, and every element of the workplace contributes to overall productivity.

Lean management encourages a culture of continuous improvement where every employee plays an active role in identifying inefficiencies and implementing solutions. By standardizing processes, teams can achieve consistency and predictability, reducing errors and improving quality. This approach not only enhances productivity but also fosters a safer, more fulfilling work environment by minimizing unnecessary steps and tasks, ultimately leading to increased job satisfaction and better overall performance.

The Core Principles of 5S Training and Its Role in Workplace Organization

The core principles of 5S training are foundational to the lean management philosophy, promoting a highly organized and efficient workplace. This rigorous program encompasses five Japanese words: seiri (sort), seiton (set in order), seiso (shining clean), seiketsu (standardize), and shitsuke (sustain). Each stage guides employees through an extensive process of sorting, arranging, and maintaining a pristine work environment. By implementing 5S, teams can easily identify necessary tools and resources, streamlining workflows and enhancing overall productivity.

Beyond mere organization, 5S training drives continuous improvement and process standardization. It encourages workers to question every aspect of their tasks and eliminate unnecessary steps or clutter. This disciplined approach fosters a culture of sustainability where maintaining order becomes second nature. As a result, teams can focus more on value-added activities, leading to increased efficiency and improved quality in all aspects of the business.

Lean Management Techniques for Streamlining Processes and Boosting Productivity

In the realm of lean management, streamlining processes and boosting productivity are paramount to achieving operational excellence. One powerful tool in this pursuit is 5S training, a methodology that emphasizes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these practices, organizations can create an environment conducive to efficiency, where every element serves a purpose and contributes to continuous improvement.

Lean management techniques, rooted in the Japanese concept of Kaizen, focus on eliminating waste and maximizing value. Process standardization plays a crucial role here, ensuring that tasks are completed consistently and effectively. This not only reduces errors but also empowers employees by providing clear guidelines and fostering a culture of ownership. When combined with 5S continuous improvement initiatives, these techniques create a dynamic and responsive workplace, where productivity is elevated and waste is minimized, ultimately driving business success.

Implementing Continuous Improvement with 5S: A Step-by-Step Guide

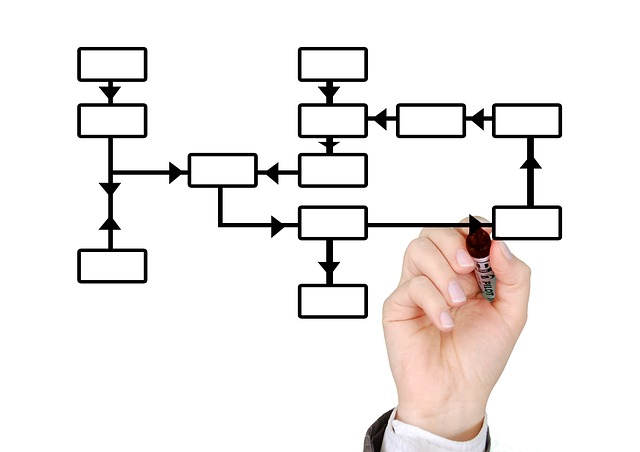

Implementing Continuous Improvement with 5S is a powerful approach that aligns perfectly with lean management principles. This step-by-step guide focuses on workplace organization and process standardization, helping teams enhance efficiency and productivity. The 5S methodology involves five key disciplines: Sort, Set in Order, Shine (Clean), Standardize, and Sustain.

By following this structured framework, organizations can systematically transform their workspace, eliminating waste and streamlining processes. Sort involves identifying and removing unnecessary items; Set in Order ensures everything has a designated place for easy access; Shine emphasizes regular cleaning to maintain a tidy environment; Standardize institutionalizes these practices through clear guidelines; and Sustain focuses on continuous improvement, ensuring the 5S principles remain embedded in the workplace culture over time.

Process Standardization: Creating Consistency and Reducing Waste

Process Standardization is a core principle of lean management, aiming to create consistency across tasks and reduce waste. This involves implementing well-defined processes that every employee understands and follows. The 5S training methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—is a popular tool for achieving this. By sorting through workspace clutter and establishing clear organizational systems, teams can streamline their workflows. Each ‘S’ represents a step in the process improvement journey, encouraging workers to maintain order and adhere to standardized procedures.

This standardization ensures that tasks are completed efficiently, minimizing errors and delays. It also fosters a culture of continuous improvement where employees actively participate in identifying inefficiencies and implementing solutions. Regular reviews and updates to processes ensure they remain relevant and effective, contributing to overall workplace organization and productivity gains.

Real-World Applications: Success Stories of Lean Workplace Transformation

In recent years, numerous organizations have successfully embraced the Lean workplace philosophy, leading to significant improvements in efficiency and productivity. One of the key drivers behind this transformation is 5S training – a systematic approach that includes sorting, setting in order, shining (cleaning), standardizing, and sustaining. Companies across various sectors have implemented 5S methodologies to achieve remarkable results.

For instance, manufacturing giants have utilized 5S continuous improvement practices to streamline production lines, reducing waste and enhancing product quality. Similarly, service industries have adopted workplace organization techniques to optimize workflow processes, leading to better customer satisfaction. The success of these initiatives lies not only in the implementation of 5S training but also in leveraging lean management principles to foster a culture of process standardization and continuous improvement within their workforce.

The Lean workplace philosophy offers a transformative approach to efficiency and productivity. By combining principles from 5S training with lean management techniques, organizations can create highly organized, streamlined processes that reduce waste and boost output. Implementing 5S continuous improvement methodologies, as showcased in real-world success stories, enables businesses to cultivate an environment of ongoing enhancement. Process standardization is a key component, ensuring consistency and minimizing errors. Adopting these strategies not only enhances operational excellence but also fosters a culture of continuous learning and innovation within the workplace.