The Lean Workplace Philosophy, based on Toyota's Lean Manufacturing method, aims to eliminate waste and maximize value across all business processes. Central to this is the 5S training methodology (Sort, Set in Order, Shine, Standardize, Sustain), which fosters continuous improvement, streamlines operations, minimizes errors, and boosts productivity. By promoting process standardization and empowering employees to identify inefficiencies, lean management creates highly organized, efficient workspaces that enhance workflow predictability, customer satisfaction, and business competitiveness. 5S training is a powerful tool for achieving optimal workplace organization, leading to significant gains in productivity, quality, and employee satisfaction.

“Discover the transformative power of Lean workplace philosophy, a game-changer in modern office environments. This approach emphasizes efficiency and productivity through principles like 5S training, a proven method for workspace optimization. We’ll explore the core ideas of lean management, focusing on process standardization and continuous improvement. By implementing 5S techniques, businesses can achieve exceptional organization and streamline workflows. Dive into this comprehensive guide to unlock the secrets of a Lean workplace, enhancing productivity and creating a more efficient operation.”

- Understanding Lean Workplace Philosophy: A Brief Overview

- The Core Principles of Lean Management

- Implementing 5S Training for Optimal Workspace Organization

- Continuous Improvement Through 5S: A Framework for Success

- Process Standardization: Streamlining Workflows for Efficiency

Understanding Lean Workplace Philosophy: A Brief Overview

The Lean Workplace Philosophy is a systematic approach to workplace organization and efficiency inspired by Toyota’s production system, known as the Lean Manufacturing method. At its core, Lean emphasizes eliminating waste while maximizing value in all business processes. This philosophy has evolved far beyond manufacturing, finding its place in various sectors including service industries, healthcare, and office environments.

Lean management involves implementing tools like the 5S training methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—to achieve workplace organization and continuous improvement. By promoting process standardization and fostering a culture of continuous learning, organizations can streamline operations, reduce errors, and enhance overall productivity. This approach encourages employees to identify inefficiencies and suggests improvements at every level, ensuring an ever-optimizing work environment.

The Core Principles of Lean Management

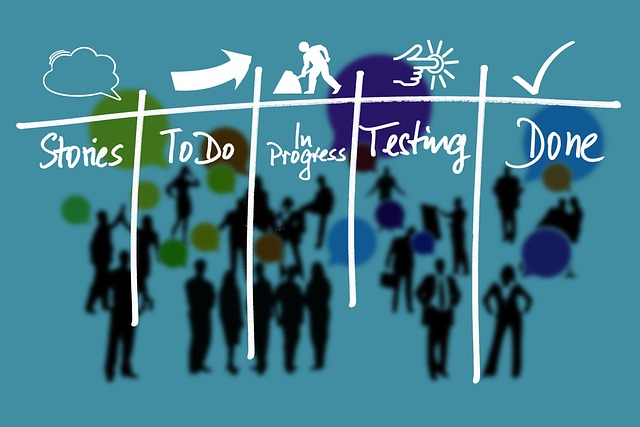

The core principles of Lean Management revolve around creating a highly organized and efficient workplace through a systematic approach known as 5S training. This involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these practices, organizations achieve optimal workflow and minimize waste, enhancing overall productivity.

5S continuous improvement drives workplace organization by fostering an environment where every element has a defined purpose. Process standardization ensures that tasks are executed consistently, reducing errors and improving quality. This philosophy leverages visual management tools to make processes transparent, empowering employees to identify and eliminate inefficiencies, ultimately contributing to a leaner, more agile business.

Implementing 5S Training for Optimal Workspace Organization

Implementing 5S Training is a powerful step towards achieving optimal workplace organization within the framework of Lean management principles. This methodology, rooted in Japanese manufacturing practices, promotes a culture of continuous improvement and process standardization. By teaching employees the 5S principles—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organizing and maintaining a workspace becomes a collaborative effort. Each ‘S’ represents a specific step in a structured approach to declutter, streamline, and enhance productivity.

The training encourages workers to take ownership of their work areas, ensuring everything has its place. This not only improves visual order but also facilitates faster, more efficient workflows. Regular 5S practice enables teams to identify and eliminate waste, enhancing overall workplace organization. By integrating these practices into daily routines, organizations can sustain a lean and productive environment, fostering a culture where continuous improvement is everyone’s responsibility.

Continuous Improvement Through 5S: A Framework for Success

In the realm of lean management, continuous improvement is a cornerstone principle. One powerful framework that drives this concept is 5S—a systematic approach to workplace organization and process standardization. This method involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke) work areas, tasks, and processes.

5S training equips employees with the skills to identify waste, streamline operations, and create an environment conducive to efficiency. By implementing these five steps, organizations can achieve significant improvements in productivity, quality, and overall workplace satisfaction. The continuous improvement aspect comes from the constant evaluation and refinement of standard operating procedures, ensuring that the workplace remains optimized over time.

Process Standardization: Streamlining Workflows for Efficiency

Process Standardization is a core aspect of the lean workplace philosophy, focusing on streamlining workflows to enhance efficiency and productivity. This involves implementing structured processes that eliminate waste and optimize resource utilization. One effective method is 5S training, which teaches employees to sort, set in order, shine (clean), standardize, and sustain organized workspaces. By adopting 5S continuous improvement practices, organizations can achieve remarkable workplace organization.

Lean management promotes a culture where every step of a process is scrutinized for improvements, ensuring that tasks are performed in the most efficient manner possible. Standardization allows for predictable outcomes, reduces errors, and enables teams to focus on value-added activities. This, in turn, leads to increased customer satisfaction and business competitiveness.

The lean workplace philosophy offers a transformative approach to optimizing productivity and efficiency. By embracing core principles like those outlined in this article—from understanding the concept to implementing 5S training and standardizing processes—businesses can create an environment that fosters continuous improvement. This framework ensures a well-organized workspace, streamlining workflows, and ultimately driving success in today’s competitive market. With a focus on efficiency, lean management empowers teams to achieve remarkable results while maintaining a balanced and sustainable work environment.