5S training, rooted in lean management principles, is a powerful tool for optimizing workplace organization and minimizing operational waste. This structured approach comprises five pillars: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By implementing these practices, businesses create efficient workflows, reduce errors, enhance productivity, and foster a culture of continuous improvement. Regular audits and feedback loops reinforce these gains, leading to significant operational waste reduction and overall business performance improvements.

In today’s competitive business landscape, minimizing operational waste is not just a best practice but a necessity. Operational waste can cripple productivity, inflate costs, and hinder growth. This comprehensive guide delves into effective strategies to identify and eliminate waste in the workplace. We explore essential techniques like 5S training for organization and efficiency, applying Lean management principles to streamline processes, implementing process standardization, fostering continuous improvement through regular audits, and utilizing tools that sustain an efficient operational environment.

- Understanding Operational Waste: Identifying Areas for Improvement

- The Role of 5S Training in Workplace Organization and Efficiency

- Lean Management Principles: Streamlining Processes for Maximum Output

- Process Standardization: Creating Consistency and Reducing Errors

- Continuous Improvement Through Regular Audits and Feedback

- Tools and Techniques to Sustain an Efficient Operational Environment

Understanding Operational Waste: Identifying Areas for Improvement

Understanding Operational Waste involves recognizing inefficiencies and unnecessary efforts within daily operations. By implementing 5S training, a structured approach to workplace organization, businesses can identify areas for improvement. The 5S methodology—Sort, Set in Order, Shine, Standardize, Sustain—serves as a framework for creating an organized and streamlined environment. This method encourages employees to only keep what is essential, maintain order, and continuously improve processes.

Lean management principles complement 5S by focusing on process standardization and elimination of waste. Through regular assessments, organizations can pinpoint inefficiencies, such as excessive motion or inventory accumulation, that hinder productivity. Adopting a culture of continuous improvement ensures that every step in a process is evaluated for potential enhancements, ultimately leading to increased effectiveness and reduced operational waste.

The Role of 5S Training in Workplace Organization and Efficiency

The Role of 5S Training in Workplace Organization and Efficiency

In today’s competitive business landscape, efficient workplace organization is a key driver for success. Among various lean management methodologies, 5S training stands out as a powerful tool to achieve both operational excellence and continuous improvement. The 5S framework—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—provides a systematic approach to streamline processes and minimize waste. By implementing 5S principles, organizations can transform their workspace into a structured, intuitive environment that enhances productivity and reduces errors.

Effective 5S training goes beyond simply teaching the five steps; it fosters a culture of discipline and continuous improvement. Through rigorous process standardization, employees learn to identify and eliminate non-value-added activities, streamlining workflows and enhancing overall efficiency. This not only contributes to improved quality and reduced costs but also empowers workers to take ownership of their roles, driving organizational success in an ever-evolving market.

Lean Management Principles: Streamlining Processes for Maximum Output

Lean Management Principles are a set of strategies that focus on streamlining processes and eliminating waste in the workplace, aiming to maximize output efficiency. The core concept revolves around identifying and removing non-value-added activities, ensuring every task contributes to the final product or service. One powerful tool within this philosophy is 5S training, a methodology that encourages workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices.

By implementing 5S continuous improvement strategies, businesses can achieve better process standardization, reducing errors and enhancing productivity. This involves regularly reviewing workflows, eliminating unnecessary steps, and creating standardized procedures that promote efficiency and quality control. Lean Management, with its emphasis on workplace organization and process optimization, is a game-changer for minimizing operational waste, fostering a culture of continuous improvement across all sectors.

Process Standardization: Creating Consistency and Reducing Errors

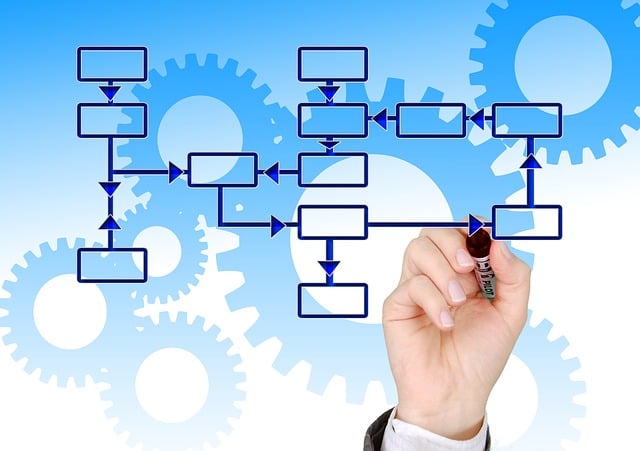

Process Standardization is a powerful tool for minimizing operational waste in any business. By creating consistent workflows and established procedures, companies can significantly reduce errors and inefficiencies. This is where 5S training comes into play—a method derived from lean management principles that promotes workplace organization. The ‘5S’ stands for Sort, Set in Order, Shine (Clean), Standardize, and Sustain, providing a structured framework to optimize the work environment and processes.

Implementing 5S continuous improvement ensures that every step of an operation is meticulously planned and executed, eliminating unnecessary steps and enhancing productivity. Process standardization, when coupled with regular training, fosters a culture of precision and quality control, allowing employees to focus on their tasks with greater efficiency. This approach not only reduces waste but also improves overall workplace morale and performance.

Continuous Improvement Through Regular Audits and Feedback

Regular audits and feedback loops are essential components of a successful operational waste minimization strategy. By implementing 5S training and lean management principles, organizations can drive continuous improvement in workplace organization. These methods, including process standardization, promote an environment where every step is examined for efficiency and every item has a designated place, reducing unnecessary movements and errors.

Through periodic audits, teams can identify areas of improvement, address inefficiencies, and standardize processes. Feedback from employees at all levels is crucial in this process, as they often possess valuable insights into daily operations. By fostering a culture that encourages open communication and constructive feedback, organizations can ensure their strategies remain aligned with the evolving demands of the workplace, ultimately leading to significant operational waste reduction.

Tools and Techniques to Sustain an Efficient Operational Environment

Maintaining an efficient operational environment requires a structured approach to eliminate waste and improve productivity. One powerful method is adopting the 5S training methodology, which stands for Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This comprehensive system involves transforming the workplace into an organized, streamlined space, minimizing clutter and maximizing productivity. By teaching employees the principles of 5S, organizations can foster a culture of continuous improvement, where every action contributes to process efficiency.

Integrating lean management practices further enhances these efforts. Process standardization ensures that tasks are executed consistently, reducing errors and waste. This involves documenting and optimizing workflows, making them as efficient as possible. Regular reviews and ongoing 5S continuous improvement initiatives ensure the workplace remains organized and optimized for productivity. These techniques, when implemented together, create a robust framework for minimizing operational waste, driving cost savings, and enhancing overall business performance.

By implementing a combination of 5S training, lean management principles, process standardization, and regular audits, organizations can significantly minimize operational waste. These strategies foster an efficient and organized workplace, streamlining processes to maximize output while reducing errors. Continuously seeking feedback and utilizing tools for sustained improvement ensures that these practices remain effective over time, ultimately contributing to a healthier bottom line and enhanced productivity.