Implementing 5S training, a lean management methodology, optimizes workplace organization through process standardization. By focusing on sorting, setting in order, cleaning, standardizing, and sustaining, this continuous improvement approach streamlines processes, reduces waste, enhances productivity, quality control, and fosters a culture of ongoing learning, ultimately driving operational excellence and customer satisfaction.

“Unleash your business’s full potential with an operational excellence framework—a strategic approach to streamline processes and enhance overall performance. This comprehensive guide delves into essential components for achieving operational mastery. We explore foundational concepts like understanding basic framework principles and the power of 5S training for optimal workplace organization.

Discover how integrating Lean management principles and fostering continuous improvement can drive efficiency. Furthermore, learn why standardizing processes is a critical roadmap to achieving unparalleled business success through enhanced productivity and reduced waste.”

- Understanding Operational Excellence Framework Basics

- Implementing 5S Training for Workplace Organization

- Integrating Lean Management Principles and Continuous Improvement

- Standardizing Processes: A Roadmap to Efficiency

Understanding Operational Excellence Framework Basics

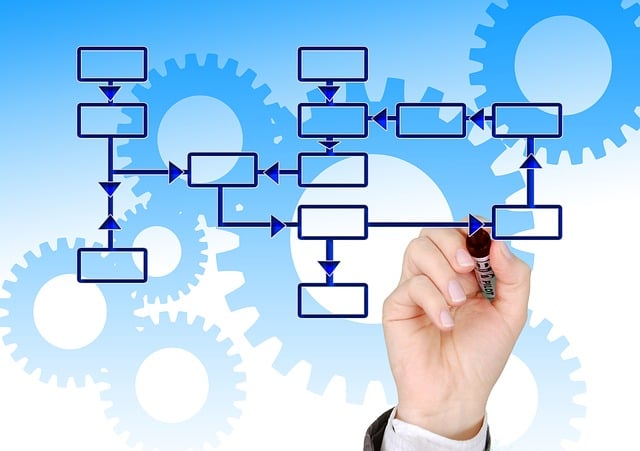

Operational Excellence Frameworks are designed to help organizations streamline their processes and enhance overall efficiency. At the core of this concept lie principles such as 5S training and lean management, which focus on workplace organization and continuous improvement. The 5S method—Sort, Set in Order, Shine (Clean), Standardize, Sustain—is a powerful tool for implementing process standardization, ensuring every workspace is orderly and efficient. Lean management, meanwhile, involves identifying and eliminating waste in various forms, be it time, motion, or resources.

These frameworks aren’t just about creating a visually tidy environment; they aim to cultivate a culture of continuous improvement where every employee contributes to enhancing processes and reducing non-value-added activities. By adopting practices like 5S continuous improvement, organizations can achieve higher levels of productivity, quality, and customer satisfaction. Process standardization ensures that tasks are performed consistently, minimizing errors and maximizing output.

Implementing 5S Training for Workplace Organization

Implementing 5S Training for Workplace Organization is a strategic move towards achieving operational excellence in any business. 5S, a lean management methodology originating from Japan, focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining workplace organization. This continuous improvement approach not only enhances efficiency but also creates a safer, more productive environment.

By integrating 5S training into daily operations, companies can streamline processes, eliminate waste, and promote a culture of accountability. Process standardization becomes second nature as employees learn to question every step in the workflow, ensuring that only value-added activities remain. This disciplined approach leads to improved productivity, reduced errors, and enhanced overall workplace organization.

Integrating Lean Management Principles and Continuous Improvement

Integrating Lean Management principles with Continuous Improvement methodologies is a powerful strategy for achieving operational excellence. This involves adopting practices like 5S training to enhance workplace organization, ensuring every space and process is optimized for efficiency and productivity. The 5S method—Sort, Set in Order, Shine (Clean), Standardize, Sustain—provides a structured framework for workplace organization, laying the groundwork for continuous improvement initiatives.

By integrating Lean Management, organizations can streamline processes through standardization, eliminate waste, and reduce errors. This encourages teams to focus on value-adding activities, fostering an environment of ongoing learning and enhancement. Continuous Improvement, when combined with 5S principles, becomes a dynamic process that drives operational efficiency, improves quality, and ultimately enhances customer satisfaction.

Standardizing Processes: A Roadmap to Efficiency

Standardizing processes is a fundamental aspect of achieving operational excellence, and it starts with implementing effective workplace organization strategies. One proven approach is adopting 5S training methodologies, which originated from lean management principles. This involves sorting, setting in order, shining (cleaning), standardizing, and sustaining—a continuous improvement cycle that ensures every workspace is organized efficiently. By teaching employees the 5S method, organizations can create a culture of disciplined workflow management.

Workplace organization transcends mere aesthetics; it’s about streamlining processes to eliminate waste. Standardization allows for consistent production or service delivery, reducing errors and enhancing quality control. In essence, process standardization enables businesses to optimize their operations, making them more competitive in today’s fast-paced market.

An operational excellence framework is a powerful tool for transforming any business. By combining foundational knowledge with practical strategies like 5S training and lean management principles, organizations can achieve remarkable workplace organization and efficiency. Integrating continuous improvement methods further ensures that progress remains a priority. Ultimately, adopting process standardization practices across the board leads to significant gains in productivity, quality, and overall operational success.