Organizational Behavior Strategies, particularly 5S training and Lean management, drive business success by fostering motivated, engaged workforces. These techniques streamline processes, enhance efficiency, reduce waste, and empower employees through standardized, well-organized workspaces. Case studies demonstrate their applicability across industries, boosting productivity, quality control, and customer experiences while navigating dynamic markets.

In today’s competitive business landscape, understanding and implementing effective organizational behavior strategies is a game-changer. This article delves into the essential elements of success, starting with a foundational exploration of Organizational Behavior Strategy. We examine key practices like 5S training for lean management and workplace organization, emphasizing its role in continuous improvement. Additionally, we dissect the benefits and challenges of structured approaches to efficiency, supported by compelling case studies from real-world applications of these strategies, focusing on process standardization.

- Understanding Organizational Behavior Strategy: A Foundation for Success

- The Role of 5S Training in Lean Management and Workplace Organization

- Implementing Process Standardization for Continuous Improvement

- Benefits and Challenges of a Structured Approach to Workplace Efficiency

- Case Studies: Real-World Applications of Organizational Behavior Strategies

Understanding Organizational Behavior Strategy: A Foundation for Success

Understanding Organizational Behavior Strategy is pivotal to achieving success in any business environment. It involves cultivating a culture where employees are engaged, motivated, and aligned with organizational goals. This foundation starts with implementing effective strategies like 5S training, a Lean management approach that focuses on workplace organization. By streamlining processes through 5S continuous improvement, organizations can enhance efficiency and productivity.

Process standardization is another key element, ensuring that tasks are completed consistently and effectively. This not only improves quality but also fosters a sense of ownership and pride among employees. When combined with robust training programs, these strategies create a dynamic where every team member contributes to the overall success, leading to increased innovation and adaptability in an ever-changing market.

The Role of 5S Training in Lean Management and Workplace Organization

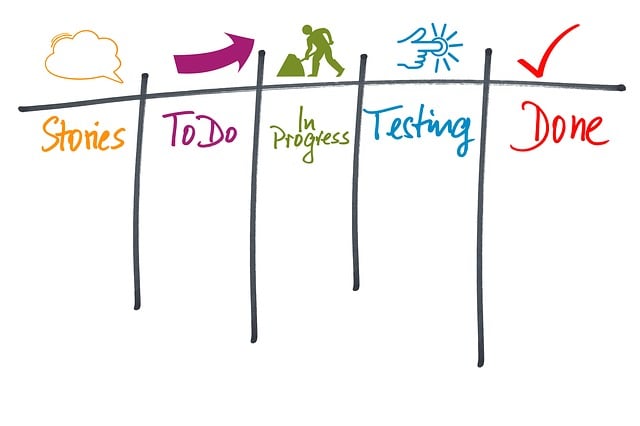

The role of 5S Training in Lean Management and Workplace Organization is pivotal. This methodology, which encompasses Sort, Set in Order, Shine, Standardize, and Sustain, serves as a powerful tool for streamlining processes, enhancing efficiency, and fostering a culture of continuous improvement within organizations. By focusing on eliminating waste, organizing spaces, and standardizing processes, 5S training empowers employees to take an active role in improving their work environment. This not only boosts morale but also leads to increased productivity and reduced errors.

In the context of Lean Management, 5S training facilitates the implementation of process standardization, ensuring that tasks are executed consistently and efficiently. This standardization is achieved through meticulous sorting and organization, where every item has its designated place. The ‘Shine’ aspect involves thorough cleaning and inspection, revealing potential issues or inefficiencies. Once identified, these problems can be addressed, leading to further optimization. Sustaining these practices through ongoing training and cultural integration ensures that workplace organization remains a priority, fostering an environment conducive to continuous improvement.

Implementing Process Standardization for Continuous Improvement

Implementing Process Standardization for Continuous Improvement is a cornerstone of successful Organizational Behavior strategies. By adopting lean management principles and 5S training, organizations can achieve exceptional workplace organization. The 5S method—Sort, Set in Order, Shine (Clean), Standardize, Sustain—provides a structured framework to optimize work processes. This involves systematically removing waste, organizing tools and equipment, and ensuring every employee follows standardized procedures.

Process standardization facilitates continuous improvement by creating an environment where inefficiencies are easily identifiable and manageable. It empowers employees to take ownership of their roles, fostering a culture of collaboration and innovation. Regular 5S audits and ongoing training reinforce these practices, driving sustained enhancements in productivity and overall organizational performance.

Benefits and Challenges of a Structured Approach to Workplace Efficiency

A structured approach to workplace efficiency through methods like 5S training and lean management offers significant benefits. By implementing process standardization and workplace organization, businesses can achieve higher productivity levels and reduced waste. The 5S continuous improvement philosophy fosters an environment where employees are engaged in maintaining a clean, sorted, and standardized workspace, leading to smoother operations and enhanced quality control. This strategic approach not only improves individual tasks but also encourages collaboration and problem-solving skills among teams.

However, adopting a structured approach is not without its challenges. Resistance to change can be a significant hurdle, as employees may need time to adapt to new processes and tools. Additionally, ensuring consistent adherence to standardized procedures across different departments or shifts can be difficult. Organizations must invest in comprehensive training and regularly reinforce the importance of 5S principles and lean management practices for sustained success.

Case Studies: Real-World Applications of Organizational Behavior Strategies

Case studies offer a powerful tool to understand and demonstrate the real-world application of Organizational Behavior strategies. By examining successful transformations within various organizations, businesses can learn practical lessons on implementing change and enhancing productivity. For instance, many companies have adopted 5S training and lean management principles to revolutionize their workplace organization. This method involves sorting, setting in order, shining a light (on processes), standardizing, and continually improving (5S continuous improvement) to create an efficient and streamlined environment.

These strategies are not limited to manufacturing; they can be adapted for service industries to enhance customer experience and employee satisfaction. Process standardization ensures consistency, reducing errors and waste. For example, a retail store might use 5S techniques to optimize inventory management, ensuring products are easily accessible and visible, thus improving sales and customer satisfaction.

Organizational behavior strategies, encompassing 5S training in lean management and workplace organization, process standardization for continuous improvement, and structured approaches to efficiency, offer substantial benefits. These methods not only enhance productivity but also foster a more organized and engaged workforce. By implementing these strategies through real-world case studies, businesses can navigate complex operational challenges, ultimately achieving greater success in today’s competitive landscape. Keywords like 5S training, lean management, workplace organization, 5S continuous improvement, and process standardization underscore the core practices driving this transformative change.