The Standardized Work Methodology uses lean management principles to optimize workplace organization and efficiency through 5S training (Sort, Set in Order, Shine, Standardize, Sustain). This Japanese method eliminates waste, organizes tools, maintains cleanliness, and establishes consistent standards, fostering a culture of process standardization, boosting productivity, quality, and safety, driving long-term operational excellence. Regular 5S continuous improvement initiatives ensure standardized processes remain effective, cultivating a culture of quality and efficiency.

“Unleash the power of efficient and organized workflows with Standardized Work Methodology. This comprehensive guide explores essential practices for transforming your workplace. From understanding the fundamentals to implementing process standardization, we delve into proven strategies like 5S training and Lean Management principles. Discover how these techniques enhance productivity, streamline operations, and drive continuous improvement. By adopting these methods, organizations can achieve long-lasting efficiency and stay ahead in today’s competitive landscape.”

- Understanding Standardized Work Methodology

- The Role of 5S Training in Workplace Organization

- Lean Management Principles for Continuous Improvement

- Implementing Process Standardization for Longevity

Understanding Standardized Work Methodology

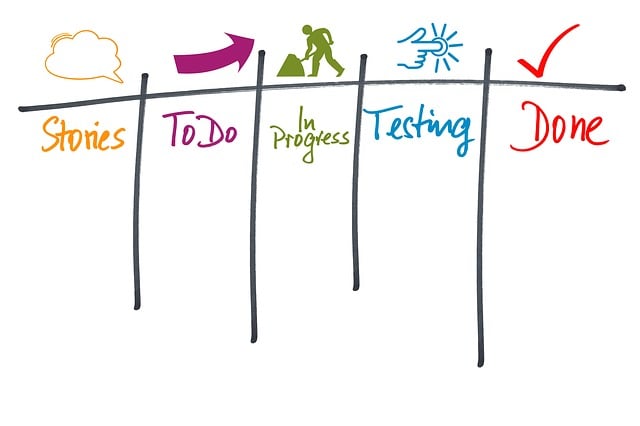

Standardized Work Methodology is a systematic approach to optimizing workplace organization and efficiency, deeply rooted in lean management principles. It involves a comprehensive process of identifying, documenting, and streamlining work processes to eliminate waste and enhance productivity. The core of this methodology lies in the 5S training framework—Sort, Set in Order, Shine (or Clean), Standardize, and Sustain.

By applying 5S continuous improvement practices, organizations can transform their workplace into a highly organized, visually managed environment. Each ‘S’ represents a step in the process, guiding employees to maintain order, eliminate clutter, and establish consistent standards across all tasks. Process standardization ensures that every step of a workflow is clearly defined, measurable, and optimized for efficiency, fostering a culture of quality and continuous improvement within the organization.

The Role of 5S Training in Workplace Organization

The implementation of 5S training is a pivotal step in achieving optimal workplace organization and efficiency, which are cornerstones of lean management principles. This structured approach, rooted in Japanese lean manufacturing practices, encompasses five disciplines: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By instilling these principles through comprehensive 5S training, organizations can transform their workspaces into streamlined, well-defined environments that enhance productivity and reduce waste.

Effective 5S training empowers employees to actively participate in continuous improvement processes by teaching them to identify and eliminate non-value-added activities, organize tools and materials efficiently, maintain a clean and safe workspace, and establish consistent standards across the organization. This fosters a culture of process standardization that not only improves productivity but also ensures quality and safety, ultimately contributing to long-term operational excellence.

Lean Management Principles for Continuous Improvement

The core principles of Lean Management, rooted in the renowned 5S training methodology, serve as a powerful tool for driving continuous improvement within any workplace organization. This systematic approach to process standardization focuses on eliminating waste and enhancing efficiency by creating an environment where every step is meticulously designed and optimized. By adhering to the 5S framework – Sort, Set in Order, Shine (Clean), Standardize, and Sustain – organizations can systematically transform their operations.

Sort involves identifying and eliminating unnecessary items; Set in Order ensures a logical layout for streamlined workflows; Shine emphasizes regular cleaning for a safe, efficient workspace; Standardize establishes consistent procedures; and Sustain drives continuous improvement through ongoing monitoring and adjustment. This lean management philosophy not only improves productivity but also fosters a culture of engagement where every employee plays a vital role in maintaining optimal workplace organization and efficiency.

Implementing Process Standardization for Longevity

Implementing process standardization is an integral part of ensuring longevity in any business operation. By adopting lean management principles and incorporating 5S training into your workplace organization strategy, companies can achieve a highly efficient and streamlined environment. This approach involves systematically organizing and structuring work processes to eliminate waste and reduce variability, leading to improved productivity and quality.

The 5S methodology—Sort, Set in Order, Shine, Standardize, Sustain—serves as a powerful tool for achieving process standardization. It encourages employees to maintain an organized workspace, follow established procedures, and continuously improve their work methods. Regular 5S continuous improvement initiatives ensure that the standardized processes remain effective over time, fostering a culture of quality and efficiency within the organization.

Standardized work methodology, encompassing 5S training, lean management principles, and process standardization, offers a powerful framework for enhancing workplace organization and driving continuous improvement. By implementing these practices, businesses can achieve longer-lasting efficiency gains, reduce waste, and foster an environment of ongoing optimization. This holistic approach not only transforms chaotic spaces into vibrant, organized hubs but also empowers “folks” to become integral parts of a symphony of streamlined processes, ultimately revolutionizing their work experiences.