In today's digital era, 5S training, a Japanese lean management practice, is vital for workplace safety and efficiency. Its five core principles (Sort, Set in Order, Shine, Standardize, Sustain) promote organization, eliminate hazards, maintain cleanliness, standardize procedures, and foster continuous improvement. By implementing 5S and lean management, businesses streamline workflows, reduce errors, enhance productivity, and ensure a safer work environment for sustained success.

Workplace safety initiatives are not just about compliance; they’re about fostering a culture of productivity and well-being. Effective strategies like 5S training and Lean management transform cluttered spaces into organized oases, streamlining workflows and enhancing efficiency. By integrating process standardization techniques, organizations can achieve remarkable results in workplace organization and continuous improvement. This article explores these essential components, offering insights into how a solid foundation in 5S training and lean practices paves the way for sustained success.

- Understanding the Foundation: 5S Training Essentials

- Streamlining Workflows: Implementing Lean Management

- Sustaining Success: Continuous Improvement Strategies

Understanding the Foundation: 5S Training Essentials

In today’s digital era, workplace safety initiatives are not just a regulatory requirement but a cornerstone of successful lean management. At the heart of many such programs lies 5S training—a powerful tool derived from Japanese manufacturing practices that emphasizes workplace organization and continuous improvement. The term ‘5S’ represents five fundamental principles: Sort (removing unnecessary items), Set in Order (arranging items for maximum efficiency), Shine (maintaining cleanliness), Standardize (establishing consistent procedures), and Sustain (continuing the cycle of improvement).

This training goes beyond mere organization, fostering a culture of process standardization where every employee plays a role in enhancing workplace safety. By implementing 5S principles, organizations can create a safer, more efficient environment. Sort through clutter to identify potential hazards; Set items in order to streamline workflows; Shine through regular cleaning to prevent accidents; Standardize processes to ensure consistency; and Sustain by continuously evaluating and improving practices. Such structured approaches not only improve safety but also boost productivity and employee morale.

Streamlining Workflows: Implementing Lean Management

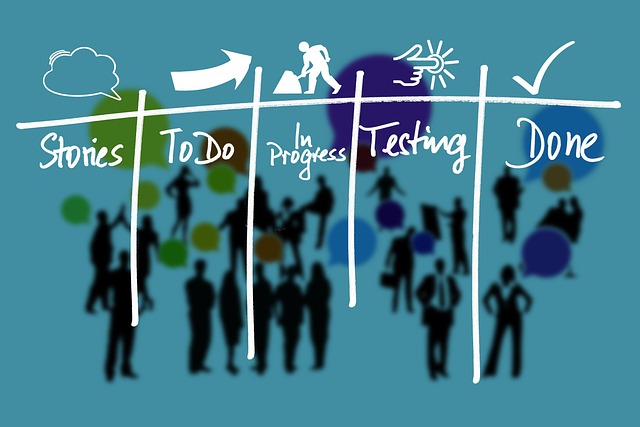

Implementing Lean Management is a powerful strategy to enhance workplace safety and efficiency. By focusing on streamlining workflows, organizations can achieve remarkable results through process standardization. This involves adopting the 5S training methodology—Sort, Set in Order, Shine, Standardize, Sustain—to create an organized and safe work environment. With this approach, every aspect of the workflow is meticulously evaluated and optimized, eliminating waste and potential hazards.

Lean Management encourages continuous improvement by fostering a culture where employees actively participate in identifying inefficiencies and proposing solutions. This collaboration ensures that workplace organization becomes a shared responsibility, leading to a safer, more productive atmosphere. Regular 5S audits and ongoing process standardization help maintain an optimal work environment, reducing accidents and improving overall job satisfaction.

Sustaining Success: Continuous Improvement Strategies

In today’s competitive business landscape, workplace safety initiatives go beyond compliance to drive sustained success. Continuous improvement strategies, like 5S training and lean management principles, are pivotal in fostering a culture of safety and efficiency. Implementing 5S—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—promotes workplace organization, enabling employees to quickly identify potential hazards and maintain a safe environment.

Process standardization, a key component of lean management, ensures that tasks are executed consistently, reducing errors and enhancing safety. By streamlining workflows and eliminating waste, organizations can create a safer, more productive workspace. These strategies not only contribute to accident prevention but also drive operational excellence, ensuring the long-term success and prosperity of any enterprise.

Workplace safety and efficiency go hand in hand, and by combining 5S training with lean management principles, organizations can create a culture of excellence. These initiatives aren’t just about implementing new systems; they’re strategies for fostering a sustainable, organized environment through continuous improvement. By streamlining workflows and standardizing processes, businesses can enhance productivity while ensuring a safer workspace. Incorporating 5S principles and embracing lean methodologies are proven game-changers, enabling organizations to thrive in today’s competitive market.