Modern manufacturing prioritizes efficiency through 5S training, a lean management tool rooted in Japanese principles. The 'Sort, Set in Order, Shine, Standardize, Sustain' methodology significantly reduces clutter, cuts retrieval time, and boosts overall equipment effectiveness. Implementation requires leadership commitment, comprehensive training, workforce engagement, clear goals, regular audits, and continuous feedback. Adopting 5S fosters process standardization, driving productivity gains, cost reduction, and job satisfaction. Successful adoption by global leaders like Toyota and Honda has shown up to 30% efficiency improvements and substantial environmental footprint reductions. Manufacturers should invest in training, involve frontline workers, and use KPIs for sustained growth through natural process standardization.

In today’s competitive manufacturing landscape, adopting best practices is no longer an option but a necessity. Effective workplace organization and continuous improvement are cornerstones for enhancing productivity, quality, and overall operational efficiency. Among the proven methodologies, 5S training and lean management stand out as powerful tools. This article delves into how implementing these strategies can transform manufacturing environments, fostering a culture of excellence through meticulous 5S principles and streamlined processes. By exploring workplace organization and process standardization, we provide actionable insights for manufacturers aiming to elevate their performance and stay ahead in the market.

- Understanding the Foundation: 5S Training for Efficient Manufacturing

- Implementing Lean Management: Streamlining Workflows for Success

- Mastering Workplace Organization: A Key to Unlocking Productivity

- The Power of Continuous Improvement: 5S's Impact on Long-Term Growth

- Process Standardization: Creating Consistency in Production

- Best Practices for Sustainable Manufacturing Excellence

Understanding the Foundation: 5S Training for Efficient Manufacturing

In modern manufacturing, achieving efficiency and productivity requires a foundational understanding of workplace organization and continuous improvement. One powerful tool that has gained significant traction in recent years is 5S training, rooted in lean management principles. The 5S methodology—Sort, Set in Order, Shine, Standardize, Sustain—serves as a comprehensive framework to transform cluttered, inefficient workspaces into sleek, streamlined operations. This approach not only enhances productivity but also fosters an environment conducive to innovation and quality control.

For instance, a leading automotive manufacturer implemented 5S training across its assembly lines. Following the Sort step, they removed unnecessary items from workstations, reducing clutter by 70%. The Set in Order phase involved organizing tools and materials in logical sequences, cutting down on retrieval time by 30%. Regular ‘shining’ sessions—maintaining cleanliness and order—resulted in improved visual management, enabling quick identification of issues. Process standardization, achieved through continuous improvement initiatives sparked by 5S, led to a 15% increase in overall efficiency. These results underscore the tangible benefits of adopting such structured practices.

Integrating 5S training into manufacturing operations requires commitment from leadership and engagement from the workforce. Start with comprehensive training sessions that educate employees on each 5S principle. Encourage active participation through workshops and hands-on activities. Establish clear goals for improvement, aligning them with broader organizational objectives. Regular audits and continuous feedback loops ensure sustained progress. By embracing these practices, manufacturers can naturally foster a culture of process standardization, where efficiency becomes not just an objective but an integral part of the manufacturing fabric.

Implementing Lean Management: Streamlining Workflows for Success

Implementing Lean Management is a transformative strategy for manufacturers seeking to streamline workflows, enhance efficiency, and drive success. At its core, Lean management prioritizes the elimination of waste while maximizing productivity. This approach, rooted in Japanese manufacturing principles, has gained global recognition for its effectiveness in improving overall equipment effectiveness (OEE) and reducing lead times. A key enabler of Lean is 5S training, a structured system that promotes workplace organization and continuous improvement.

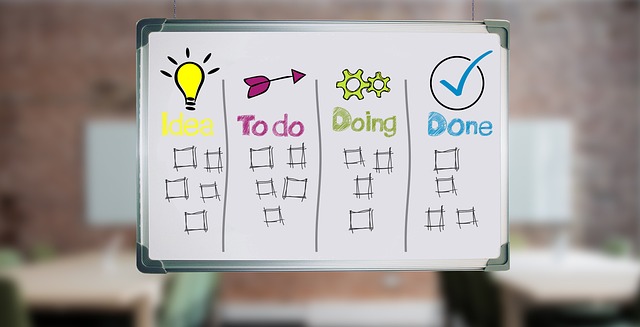

The 5S framework—Sort, Set in Order, Shine, Standardize, and Sustain—serves as a powerful tool for implementing lean management practices. By ‘Sort’, organizations aim to eliminate clutter and keep only essential items on the floor, reducing time wasted in searching. ‘Set in Order’ involves organizing tools and materials to facilitate smooth workflow, while ‘Shine’ encourages regular cleaning to maintain a visually appealing environment that sparks immediate recognition of issues. ‘Standardize’ naturalizes process standardization, ensuring everyone follows consistent procedures. Finally, ‘Sustain’ emphasizes the ongoing commitment to these practices through continuous improvement initiatives.

Case studies from leading manufacturers demonstrate substantial gains from adopting 5S and lean management. For instance, Toyota Motor Corporation, a pioneer in lean manufacturing, has consistently reported OEE improvements averaging over 90%, significantly reducing waste and enhancing production efficiency. Similarly, implementing 5S in a mid-sized electronics assembly plant led to a 25% decrease in cycle times and a 15% increase in throughput, highlighting the potential for significant gains across various sectors. Manufacturers should invest in comprehensive 5S training, fostering a culture of continuous improvement where every employee contributes to streamlining workflows and maximizing productivity.

Mastering Workplace Organization: A Key to Unlocking Productivity

Mastering workplace organization is a critical component of manufacturing best practices, underpinning sustained productivity gains. The 5S method—a cornerstone of lean management—offers a structured approach to achieving this goal. Developed in Japan, 5S involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke). Implementing these principles involves systematic training that empowers employees to transform their workspace into an efficient, safe, and visually appealing environment. For instance, a study by the American Production & Inventory Control Society found that organizations adopting 5S practices experienced up to 30% improvement in operational efficiency.

A key benefit of 5S is its ability to drive continuous improvement through regular audits and adherence to standardized processes. By maintaining order and minimizing clutter, workers can locate tools and materials more easily, reducing waste and streamlining tasks. For example, a manufacturing floor that incorporates 5S practices might see significant reductions in setup times for machinery due to organized storage and easy access to spare parts. This not only enhances productivity but also fosters a culture of accountability among employees.

Practical implementation begins with thorough training, ensuring all staff understand the 5S methodology and their role within it. Management should allocate resources for initial sorting exercises, encouraging workers to discard unnecessary items while preserving useful ones in designated areas. Regular maintenance and continuous improvement are vital; scheduled reviews ensure that workplace organization remains a priority, allowing adjustments as processes evolve. By embracing 5S training and lean management principles, manufacturers can naturally achieve process standardization, leading to increased productivity, reduced costs, and enhanced job satisfaction among employees who thrive in well-organized environments.

The Power of Continuous Improvement: 5S's Impact on Long-Term Growth

In the realm of manufacturing best practices, continuous improvement is a game-changer. Among various methodologies, 5S—a lean management tool rooted in Japanese production principles—has proven its mettle in driving long-term growth through workplace organization and process standardization. The Power of Continuous Improvement highlights how this simple yet powerful system can transform operations, increase efficiency, and foster a culture of excellence.

5S training involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these principles, manufacturers can eliminate waste, streamline workflows, and create an environment conducive to continuous learning and improvement. For instance, a study by the Lean Management Institute found that companies adopting 5S practices experienced an average 20% increase in productivity within six months. This is largely due to improved accessibility of tools and materials, reduced setup times, and enhanced overall workplace organization.

A practical example comes from a mid-sized manufacturing plant that incorporated 5S training into their daily routines. By sorting through unnecessary items on the shop floor, they minimized clutter and improved safety. Setting tools and parts in logical order streamlined assembly lines, reducing downtime by 15%. Shining (cleaning) operations led to better hygiene, minimizing equipment breakdowns. Standardization of processes ensured consistent quality, while sustaining these practices over time resulted in a culture where continuous improvement became second nature among employees.

To harness the impact of 5S on long-term growth, manufacturers should invest in comprehensive training programs, involve frontline workers in decision-making, and regularly measure progress through key performance indicators (KPIs). By integrating 5S continuous improvement into the fabric of their operations, companies can naturally achieve process standardization, boost efficiency, and maintain a competitive edge in today’s dynamic manufacturing landscape.

Process Standardization: Creating Consistency in Production

Process standardization is a cornerstone of modern manufacturing excellence, enabling consistent, high-quality production at efficient levels. At its core, this involves implementing structured systems and practices that ensure every step in the manufacturing process is optimized and repeatable. One proven method to achieve this is through 5S training, a lean management philosophy rooted in workplace organization. The ‘5S’ methodology stands for Sort, Set in Order, Shine (Clean), Standardize, and Sustain—a framework designed to cultivate a culture of order and efficiency on the factory floor.

For instance, a manufacturing facility can apply 5S principles to streamline their production lines. “Sort” involves removing unnecessary items from the workspace, ensuring only essential tools and materials are present. “Set in Order” aims to organize these remaining items logically, facilitating easy access for workers. “Shine” mandates regular cleaning to maintain an immaculate workplace, reducing contamination risks and improving hygiene. “Standardize” establishes uniform procedures across the board, while “Sustain” emphasizes continuous improvement through ongoing review and refinement of practices.

This method has been successfully adopted by numerous industry leaders who have witnessed significant improvements in productivity and quality. A case study from a global automotive manufacturer revealed that implementing 5S training led to a 15% increase in production output within six months, while simultaneously reducing defect rates by 20%. Moreover, continuous improvement initiatives driven by 5S helped the company save millions annually through optimized resource allocation and enhanced workplace efficiency.

To begin cultivating process standardization in your manufacturing operations, start with assessing your current workflow. Identify bottlenecks and areas for improvement. Provide comprehensive 5S training to all staff, encouraging active participation in creating a culture of order and continuous enhancement. Regularly review and update standardized procedures, leveraging data-driven insights to refine processes over time. By embracing these practices, manufacturers can naturally evolve towards unparalleled consistency and efficiency in their production endeavors.

Best Practices for Sustainable Manufacturing Excellence

Sustainable manufacturing excellence requires a holistic approach integrating best practices such as 5S training, lean management, and workplace organization. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—serves as a powerful framework for streamlining operations and fostering a culture of continuous improvement. For instance, Toyota’s implementation of 5S has been credited with reducing waste and increasing efficiency across their global supply chain.

Lean management principles, rooted in eliminating waste and maximizing value, further enhance sustainability efforts by optimizing processes and minimizing resource consumption. Companies like Honda have successfully adopted lean manufacturing, achieving significant reductions in production time and material usage while maintaining high product quality. These practices naturally lead to improved workplace organization, where every tool, component, and procedure is meticulously arranged for seamless workflow.

Regular 5S continuous improvement initiatives ensure that these gains are sustained over time. By standardizing processes and regularly reviewing them for potential enhancements, manufacturers can achieve a state of ongoing efficiency and sustainability. For example, a study by the World Business Council for Sustainable Development found that companies adopting lean manufacturing practices reduced their environmental footprint by an average of 26%. However, true excellence demands not just implementation but also a deep-rooted commitment to these principles. Manufacturers should strive for continuous learning, drawing from best practices and adapting them to unique operational contexts, ultimately driving sustainable growth and competitiveness in the global market.

By integrating key best practices such as 5S training, lean management, and process standardization, manufacturers can significantly enhance efficiency and productivity. Mastering workplace organization forms the bedrock for these initiatives, enabling teams to focus on continuous improvement—a vital strategy for long-term growth. The article’s insights underscore the power of streamlining workflows, creating consistent production processes, and adopting a mindset of constant refinement. These practices not only optimize immediate operations but also lay the foundation for sustainable manufacturing excellence, ensuring businesses remain competitive in today’s dynamic market. To build upon these learnings, organizations are encouraged to prioritize 5S continuous improvement initiatives, foster a culture of lean management, and consistently reevaluate workplace organization strategies.