The Lean Workplace Philosophy emphasizes eliminating waste and maximizing productivity through meticulous workplace organization and process standardization. 5S training—a cornerstone method including sorting, setting in order, shining (cleaning), standardizing, and sustainability—streamlines workflows and fosters continuous improvement. This approach boosts employee engagement, customer satisfaction, and overall efficiency by empowering teams to identify and implement sustainable solutions based on standardized processes.

“Discover the transformative power of Lean workplace philosophy – a system designed to maximize efficiency and productivity. This comprehensive guide explores key components like 5S training, laying the groundwork for organized spaces. Learn about Lean management principles and their practical application in streamlining workflows. From workplace organization techniques to continuous improvement through 5S methodology and process standardization, embrace strategies that elevate performance. Implement these insights to cultivate a culture of excellence.”

- Understanding the Lean Workplace Philosophy

- 5S Training: A Foundation for Organization

- Lean Management Principles and Their Application

- Workplace Organization: Streamlining for Efficiency

- Continuous Improvement Through 5S Methodology

- Process Standardization: Enhancing Productivity

Understanding the Lean Workplace Philosophy

The Lean Workplace Philosophy is a system that leverages tools like 5S training to create an organized, efficient, and continually improving work environment. At its core, it’s about eliminating waste – any activity or resource that doesn’t add value for the customer – through meticulous workplace organization and process standardization. This approach, deeply rooted in lean management principles, seeks to maximize productivity and employee engagement by streamlining workflows.

5S training, a cornerstone of this philosophy, involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke) the workplace. This methodical approach extends beyond mere cleanliness; it ensures that every tool and task has its place, promoting a culture of continuous improvement where everyone contributes to optimizing processes. By fostering a disciplined environment focused on value-adding activities, lean management encourages teams to identify inefficiencies and implement sustainable solutions.

5S Training: A Foundation for Organization

5S Training serves as a cornerstone in implementing lean management principles and fostering workplace organization. This method, rooted in Japanese manufacturing practices, emphasizes space utilization, order, cleanliness, and standardization (the core components of 5S). Through comprehensive training, employees learn to systematically organize their work areas, eliminating clutter and streamlining processes.

By adopting 5S continuous improvement, organizations can achieve process standardization, ensuring tasks are performed efficiently and consistently. This approach not only enhances productivity but also creates a safer, more manageable workplace environment. The structured nature of 5S encourages regular audits and ongoing refinement, allowing for constant optimization and adaptation to changing needs.

Lean Management Principles and Their Application

The Lean Management philosophy, rooted in the production methods of Toyota, emphasizes efficiency and waste elimination. Central to this approach are the 5S training principles: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. These concepts aren’t just theoretical; they’re powerful tools for enhancing workplace organization and fostering a culture of continuous improvement.

Applying Lean Management means embracing process standardization to streamline workflows and minimize variations that lead to errors and delays. By implementing 5S practices, organizations can transform their work environment into a structured, organized space that promotes productivity. This involves sorting through unnecessary items, establishing clear processes and layouts, maintaining cleanliness, and creating standardized procedures that everyone follows, ensuring consistent quality and efficiency across the board.

Workplace Organization: Streamlining for Efficiency

A lean workplace philosophy emphasizes efficient and streamlined processes, which begins with meticulous workplace organization. The 5S training methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—serves as a foundational tool for achieving this. By implementing 5S continuous improvement practices, organizations can enhance productivity by eliminating waste and clutter, ensuring that every item has its designated place. This organized environment fosters a culture of process standardization, enabling employees to focus on value-added tasks without distractions.

Workplace organization goes beyond physical spaces; it involves rationalizing workflows, automating repetitive tasks where possible, and establishing clear communication channels. Lean management encourages regular audits and continuous improvement initiatives to maintain this efficiency. Through these efforts, organizations can create a dynamic yet structured work environment that not only boosts productivity but also employee morale, ultimately driving operational excellence.

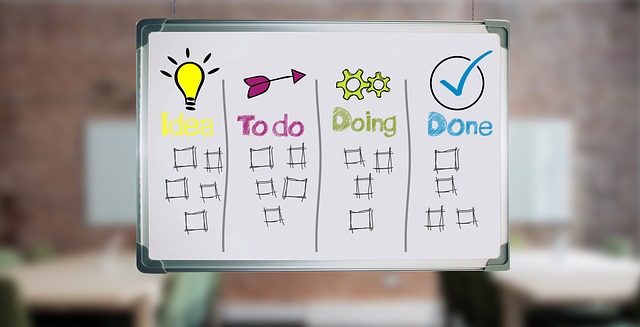

Continuous Improvement Through 5S Methodology

In a lean workplace philosophy, Continuous Improvement (Kaizen) is a core principle that drives efficiency and productivity. One powerful tool to achieve this is the 5S Methodology, which involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. This structured approach not only enhances workplace organization but also facilitates process standardization, a key aspect of lean management.

5S training equips employees with the skills to identify unnecessary items, organize workspace for optimal workflow, maintain a clean and safe environment, establish standardized work processes, and ensure continuous improvement through regular review. By implementing 5S principles, organizations can create a more efficient, ergonomic, and motivated workforce, ultimately leading to increased productivity and reduced waste.

Process Standardization: Enhancing Productivity

Process Standardization is a cornerstone of the lean workplace philosophy, focusing on creating efficient and predictable work processes. This involves implementing 5S training—a method that includes sorting, organizing, cleaning, standardizing, and maintaining—to achieve optimal workplace organization. By teaching employees to systematically arrange their workspace and follow standardized procedures, organizations can eliminate waste and inefficiencies, enhancing productivity and overall workflow.

The lean management approach emphasizes continuous improvement, encouraging regular reviews and adjustments to these processes. This not only ensures that the workplace remains orderly but also allows for quick identification and resolution of bottlenecks or areas needing refinement. Process standardization, when combined with 5S continuous improvement practices, fosters a culture of efficiency, quality, and employee engagement.

The Lean workplace philosophy offers a transformative approach to organizational efficiency. By implementing 5S training as a foundation, organizations can establish a culture of organization and standardisation. Adopting lean management principles enables businesses to streamline processes, enhancing productivity through continuous improvement. This methodology, including process standardization, proves essential in today’s competitive market, ensuring companies stay agile and responsive to meet demands effectively.