In today's dynamic work environments, prioritizing workplace safety through strategic initiatives like 5S training and lean management principles is crucial for organizational success. The 5S methodology—sorting, setting in order, shining (cleaning), standardizing, and sustaining—enhances organization, continuous improvement, and safety by streamlining processes, reducing errors, and eliminating clutter. Process standardization complements these efforts, minimizing risks and fostering a culture of high safety standards among employees. Lean management techniques, when combined with 5S practices, revolutionize workplace dynamics, creating organized, efficient, and safe environments that empower employees to maintain productivity while ensuring well-being.

Workplace safety initiatives are not just regulatory requirements; they’re essential for fostering a productive, healthy, and engaged workforce. In today’s competitive business landscape, understanding and prioritizing safety can be a game-changer. This article explores key strategies to enhance workplace safety, focusing on 5S training for efficient environments, lean management techniques for streamlined workflows, the role of workplace organization in employee well-being, and continuous improvement through 5S as a long-term strategy. Additionally, we delve into process standardization as a critical element for predictable and safe operations.

- Understanding the Importance of Workplace Safety Initiatives

- Implementing 5S Training for Efficient and Safe Environments

- Lean Management Techniques: Streamlining Workflows for Better Safety

- The Role of Workplace Organization in Enhancing Employee Well-being

- Continuous Improvement Through 5S: A Long-term Strategy

- Standardizing Processes for Predictable and Safe Operations

Understanding the Importance of Workplace Safety Initiatives

In today’s fast-paced work environments, understanding and prioritizing workplace safety initiatives is paramount for any organization. Implementing strategies that enhance security measures not only protects employees but also fosters a culture of productivity and well-being. By integrating concepts like 5S training and lean management, companies can create an organized, efficient, and safe workspace. This involves systematic processes such as sorting, setting in order, shining (cleaning), standardizing, and sustaining—known as the 5S methodology—which contribute to both workplace organization and continuous improvement.

Process standardization is another key component of successful workplace safety initiatives. It ensures that tasks are carried out consistently, reducing errors and enhancing overall efficiency. When combined with 5S continuous improvement practices, lean management techniques can revolutionize workplace dynamics. This approach not only improves workflow but also creates a safer environment by eliminating unnecessary steps, minimizing waste, and promoting a culture where every employee plays a vital role in maintaining a secure and productive workspace.

Implementing 5S Training for Efficient and Safe Environments

Implementing 5S Training for Efficient and Safe Environments

In today’s digital era, fostering a culture of safety in the workplace is more crucial than ever. One proven method to achieve this is through 5S training, rooted in lean management principles. By adopting 5S—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organizations can significantly enhance both efficiency and safety. This methodology promotes workplace organization, streamlining processes and eliminating unnecessary clutter, which reduces risks of accidents and injuries.

The continuous improvement aspect of 5S encourages regular assessments and adjustments to maintain a safe, well-organized environment. Process standardization ensures that tasks are carried out consistently, minimizing errors and maximizing productivity. As previously mentioned, this approach underscores the importance of a systematic approach to workplace safety, fostering an atmosphere where every employee plays a vital role in maintaining a vibrant and secure work environment.

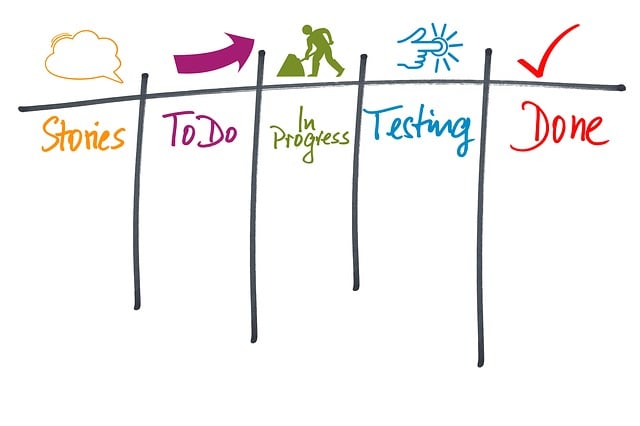

Lean Management Techniques: Streamlining Workflows for Better Safety

Lean Management Techniques play a pivotal role in enhancing workplace safety by streamlining workflows and promoting a culture of efficiency and organization. The core principle behind Lean is to eliminate waste, which can significantly reduce accidents and improve overall productivity. One powerful tool within this framework is 5S training—a methodology that involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing 5S continuous improvement practices, organizations can create a more organized and standardized work environment. This approach ensures that safety protocols are consistently followed, as every employee is trained to maintain a certain level of workplace organization.

Process standardization, another key aspect of Lean management, involves documenting and optimizing each step in a workflow. This method allows for consistent and efficient processes, reducing the risk of errors and accidents. By systematically breaking down complex tasks into manageable steps, companies can identify potential hazards more easily and implement safety measures accordingly. This not only improves overall efficiency but also fosters an environment where every employee is committed to maintaining high safety standards.

The Role of Workplace Organization in Enhancing Employee Well-being

A well-organized workplace is a crucial component of any successful safety initiative. Implementing methods like 5S training and lean management can significantly enhance employee well-being and productivity. The 5S method—Sort, Set in Order, Shine, Standardize, Sustain—is a powerful tool for achieving process standardization and creating an efficient workspace. By promoting a culture of order and organization, workplaces can minimize accidents and injuries caused by disarray and clutter. A lean management approach further complements this by focusing on eliminating waste and streamlining processes, ensuring that every aspect of the work environment is optimized for safety and comfort.

This organized landscape allows employees to easily navigate their tasks, reducing mental strain and physical hazards associated with searching for tools or documents. Additionally, 5S continuous improvement encourages regular maintenance and upkeep, which prevents potential risks from developing over time. As a result, a well-organized workplace fosters a sense of calm, enabling employees to focus on their work without distractions, ultimately contributing to improved job satisfaction and overall employee well-being.

Continuous Improvement Through 5S: A Long-term Strategy

Implementing 5S as a workplace safety initiative offers a powerful long-term strategy for continuous improvement. This Lean management philosophy emphasizes workplace organization and process standardization, ensuring every employee works in a safe, efficient, and ergonomically designed space. By following the 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organizations can create an environment conducive to safety and productivity. Regular 5S training empowers employees to identify and eliminate waste, streamline processes, and maintain a high standard of organization.

The continuous improvement aspect of 5S encourages ongoing assessment and refinement, allowing for adaption as new challenges or best practices emerge. This dynamic approach ensures that workplace safety initiatives remain relevant and effective over time, fostering a culture where every individual takes responsibility for maintaining a safe work environment.

Standardizing Processes for Predictable and Safe Operations

In today’s digital era, prioritizing workplace safety is more critical than ever. One effective strategy for achieving predictable and safe operations lies in standardizing processes through 5S training and lean management principles. This involves organizing the workspace meticulously, ensuring every tool and resource has its designated place, and fostering a culture of continuous improvement. By implementing 5S methodologies, employees learn to identify and eliminate waste, streamline workflows, and maintain an orderly environment, thereby enhancing overall safety.

Process standardization is not just about maintaining order; it empowers workers to anticipate potential hazards and take proactive measures. This approach aligns with the broader concept of 5S continuous improvement, where regular audits and adjustments ensure that safety standards remain consistent and effective. When processes are clearly defined and standardized, employees can focus on their tasks with greater clarity and confidence, ultimately contributing to a safer and more productive work environment.

Workplace safety initiatives, encompassing 5S training, lean management techniques, and process standardization, create efficient, organized environments that prioritize employee well-being. By implementing these strategies, businesses can achieve better safety outcomes while enhancing productivity through streamlined workflows and continuous improvement processes. Incorporating workplace organization principles ensures a safe, predictable workspace, fostering a culture of proactive risk mitigation and employee engagement.